MeiVac Precision MCT-8000 Cluster Tool

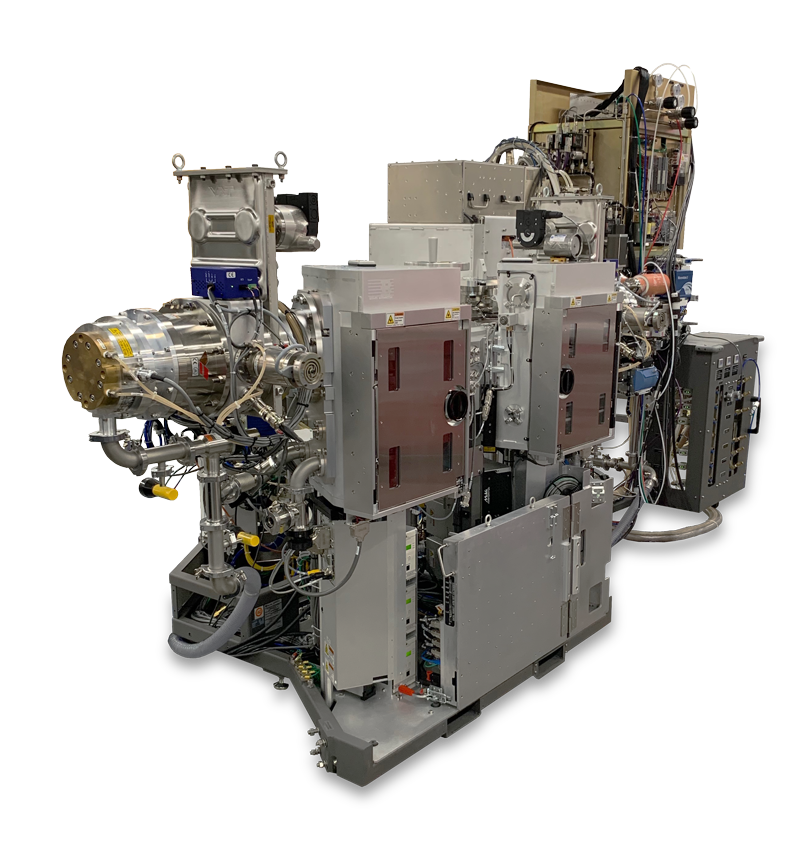

Ferrotec’s MeiVac MCT-8000 Cluster Tool was developed as a high reliability, high uptime, expandable system platform which has been optimized for hard disk drive thin film head applications.

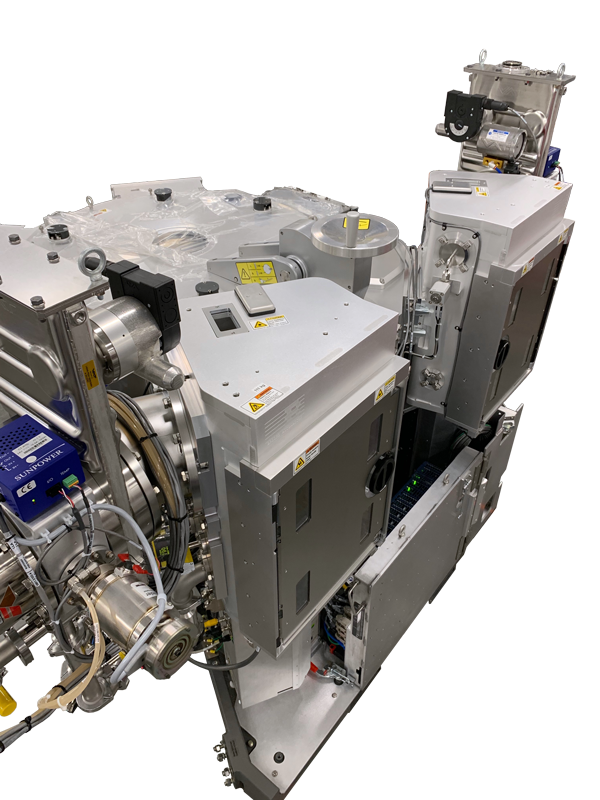

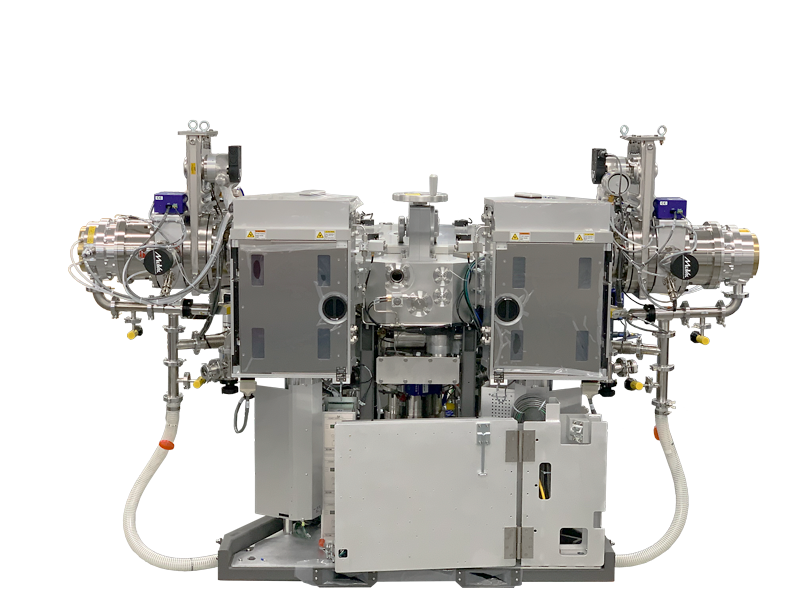

Front panel for Clean Room Environments

The MCT-8000 system front panel is installed in production clean-room environments, isolating tool components from clean room process areas.

Highlights

- Production-proven 24/7 cluster tool

- Fully automated processing of up to 200mm ∅ substrates

- Available with 2 to 4 process modules and with 2 load-locks

- Process modules are field retrofittable

- Brooks MX-600 cluster platform with Mag 7 robot

- Every chamber has a dedicated slot valve and pump stack with turbo & water pump

- Cassette present sensor, wafer present sensors, and wafer slideout sensors

- Aligner with notch detection and orientation

- Wafer temperature sensor

- Integrated RGA for system control

- Optimized for Hard Disk Drive Thin Film Head application

- Al2O3, SiO2, Ta2O5…

- From 0.2μ to 23μ for Al2O3

- O2 process capable for enhanced side wall coverage

- <1.0% sigma/mean uniformity and layer concentricity

- High rate deposition processes (>950A/min)

- Proprietary, multi-MFC gas distribution system for process modules

- Helium backside gas cooling

- RF substrate bias option to enhance deposited film properties

- Available for metal or reactive dielectric material deposition

- Windows 7 based UI and GE RX3i Programmable Logic Controller (PLC)

- Profibus communications to key components on the system

- Configurable SECS/GEM option for communication with most fabs’ Manufacturing Execution Systems (MES)

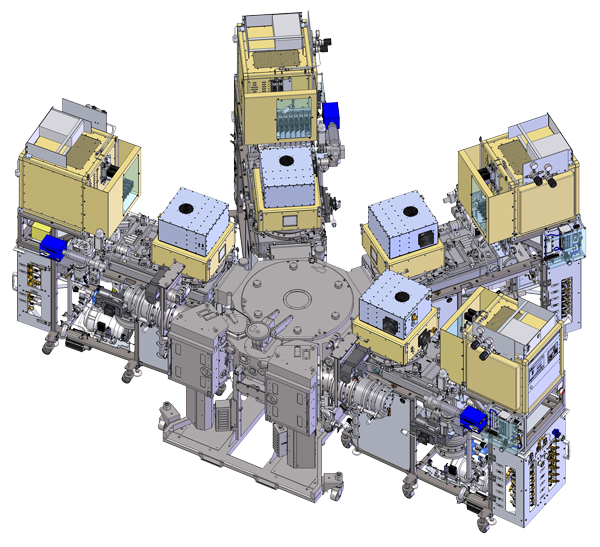

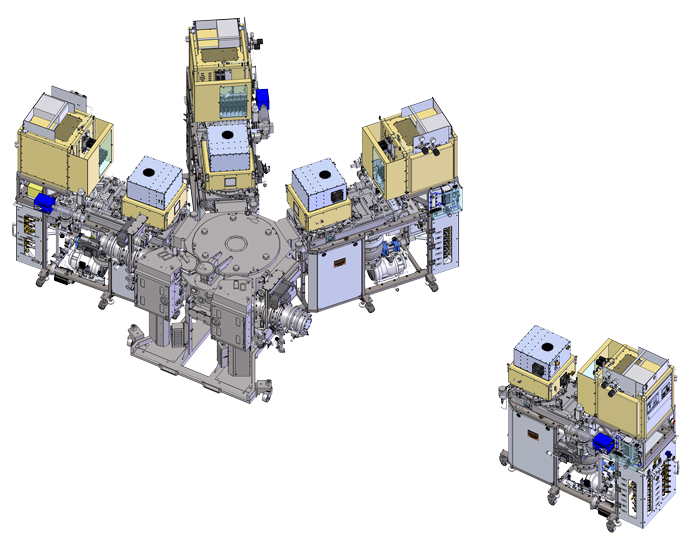

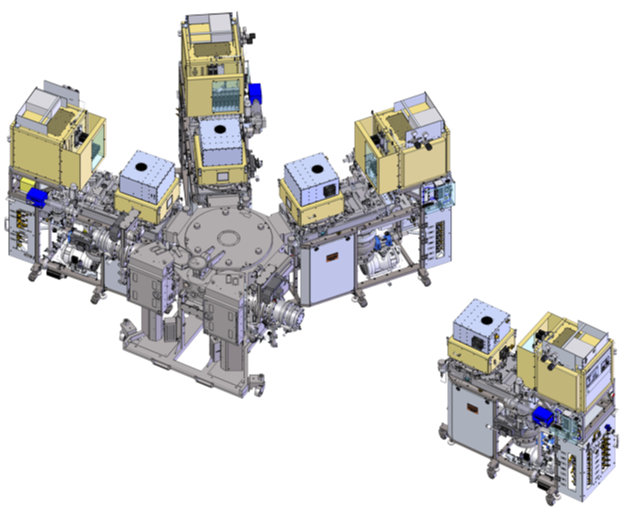

Expandable System Offers Scalable Flexibility for Production Environments

With Ferrotec’s MeiVac MCT-8000 cluster tool, you can configure the system to match your production requirements. The MCT-8000 supports up to four process modules with two load-locks. The process modules are field-retrofittable, enabling you to expand your system capacity easily.

Process Modules are Field-retrofittable

A Flexible System designed to scale with your production volumes.

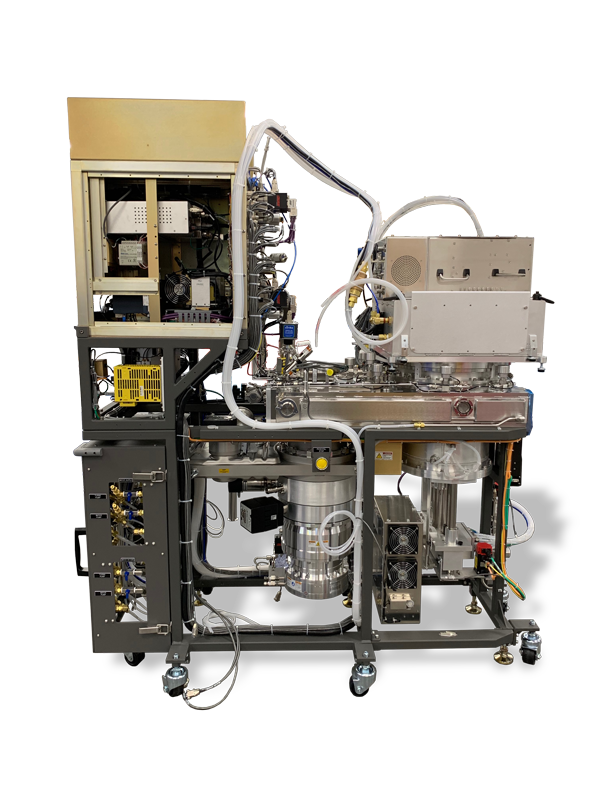

Automation at the Heart of the System

The MCT-8000 is built around a production-focused automation system. The system uses a Brooks MX-600 cluster platform with a Mag 7 robot. Every chamber has a dedicated slot valve and pump stack with a turbo pump and a water pump. The system incorporates a complete array of sensors and an integrated RGA for system control. The MCT-8000 also features a configurable SECS/GEM option for communication with fabs’ Manufacturing Execution Systems (MES).