Advanced High-Precision Thin Film Sputtering Systems

From our top-of-the-line MCT-8000 Cluster Tool to the batch throughput 2480 RF Diode system, Ferrotec’s MeiVac group has a history of designing and building high-performance thin-film deposition systems for demanding market requirements.

Precision MCT-8000 Cluster Tool

Developed as a high reliability, high uptime, expandable system platform, Ferrotec’s MeiVac MCT-8000 Cluster Tool was optimized for hard disk drive thin film head applications.

Details

Precision 602 Single Wafer System

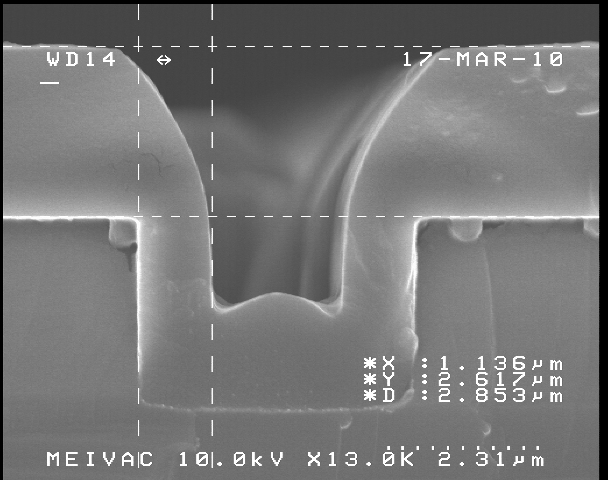

Ferrotec’s MeiVac 602 series sputtering system was developed as a high reliability, high uptime, expandable system platform for the deposition of thin alumina gap layers.

Details

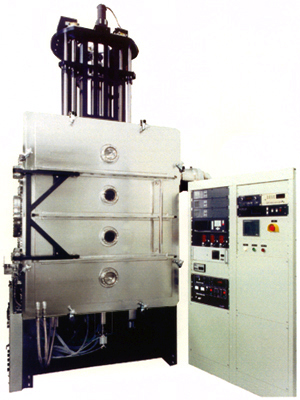

2480 RF Diode Batch System

Ferrotec’s MeiVac HEDA RF Diode sputtering system family was developed as a high throughput batch deposition system for thick alumina layers utilized in thin film heads for the magnetic storage industry.

Details

Retrofits & Upgrades

- 602/2480 GMO (Gas Management Option)

- Auto Phase Shifter/Monitor

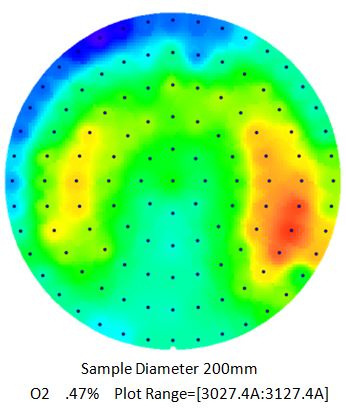

- 2480 Uniformity Enhancement Retrofit

- 602 Robot Upgrade (Brooks Platform)

- 602 Wafer Temperature Sensor

- 602/2480 Wafer Size Upgrade 5″ to 6″ to 8″

R&D and Process Improvements

Whether you need a tool for a 24/7 production fab or are still in the development phase, the MeiVac team will work with your researchers and engineers to maximize the process performance of a new or existing tool.

Details

Custom MeiVac Systems

MeiVac has a history of designing and building tools to meet customers’ unique needs.

Details